-

Process Upgrade | A&E Achieves Abundant Results in Hot Pot Process Research

Release time:2025-05-12 News section:Company News

-

Carbon fiber materials are known as the "king of new materials" and are widely used in aerospace, automotive manufacturing, wind turbine blades, sports equipment, and other fields due to their excellent properties such as high strength, lightweight, and corrosion resistance. However, the manufacturing process of carbon fiber products has always been a technical difficulty in the industry, especially how to improve the uniformity, density, and mechanical properties of products, which has become a key breakthrough for major manufacturers.

Recently, A&E has made a breakthrough in the research of hot press tank process. The hot press tank technology invested in research and development by the company can efficiently and quickly produce high-performance carbon fiber test boards, marking a solid step forward in our process upgrade in the high-end carbon fiber intelligent manufacturing field!

Hot press can process plays an important role in carbon fiber intelligent manufacturing

As a high-pressure and high-temperature curing equipment, the core principle of Autoclave is to make test molds from carbon fiber prepreg through corresponding processes, and then perform processes such as "vacuum pumping, temperature rise and pressure, cooling and demolding" through Autoclave, so that the composite material can be cured and formed in a controllable temperature and pressure environment.

The carbon fiber sheet produced through the hot pressing process has higher material density, better interlayer bonding strength, more stable dimensional accuracy, and a wider range of applications.

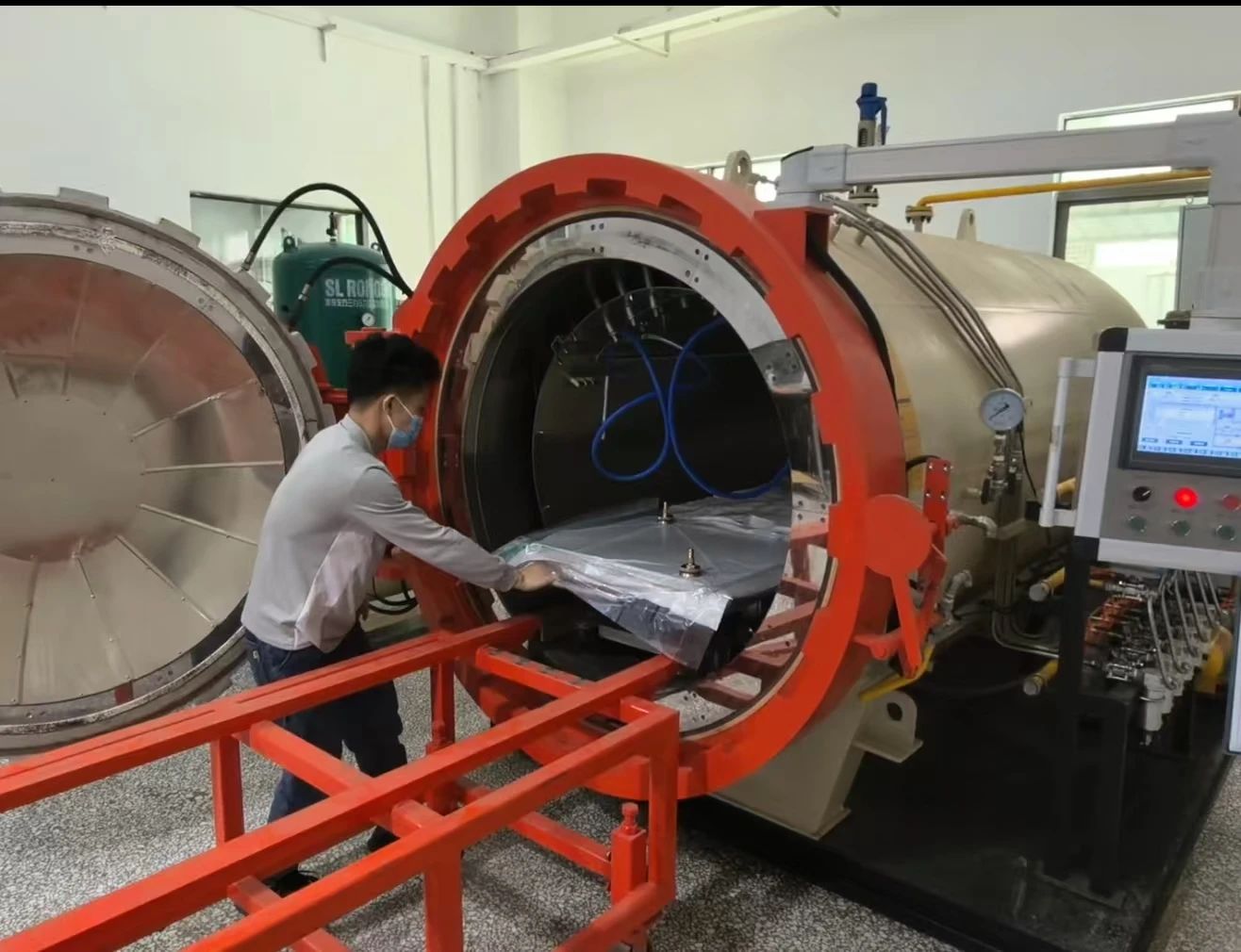

(After the prepreg testing mold is vacuum sealed, it is sent into the hot press tank chamber by the engineer)

(After the hot press tank is closed, the engineer performs fully automated process operations)

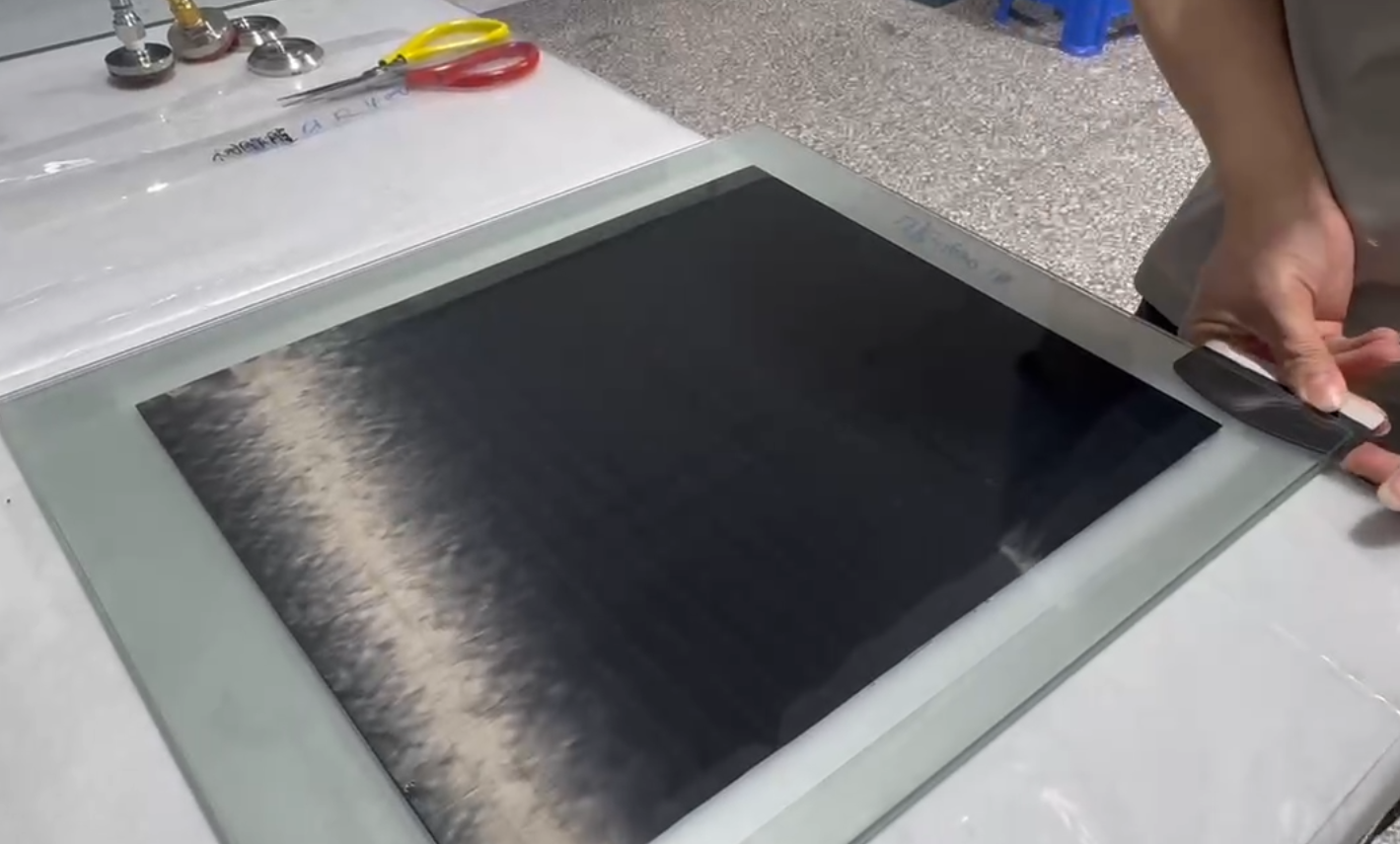

(The pre impregnated material after the hot pressing process has better performance)

A&E is committed to innovation driven intelligent manufacturing upgrade

As a leading provider of carbon fiber prepreg and carbon fiber products in China, A&E always regards technological innovation as its core strategy. In recent years, the company has continuously invested in optimizing manufacturing processes and improving production efficiency, and the research on hot press can process is an important manifestation of this strategy.

We expect that after the improvement and comprehensive implementation of the hot press tank process in the future, the curing time of our products produced through hot press tanks will be more controllable, and production efficiency will be greatly improved. Meanwhile, high-precision equipment can better reduce product defects and significantly improve product quality. More importantly, upgrading the manufacturing process will help us further expand our market layout in high-end carbon fiber fields such as aerospace and new energy vehicles.

A&E joins hands with you to create the future

The research results of the hot press can process are not only a milestone in the upgrading of A&E process, but also an important step towards high-end carbon fiber manufacturing. In the future, we will continue to explore more efficient curing solutions and promote automation and intelligent production, making carbon fiber manufacturing more precise, efficient, and environmentally friendly.

Our goal is not only to lead in technology, but also to become an outstanding participant in the global carbon fiber products industry! In the future, we will continue to increase research and development investment, work together with industry chain partners, and jointly promote the innovative application of carbon fiber in new energy, aerospace, high-end equipment and other fields, helping more high-quality carbon fiber composite materials go global!

-

Related

information

-

-

Embracing technology | A&E holds AI themed training again to empower efficient work

A&E held a special training session on the theme of "Changes brought by AI language models".

-

Pursuing excellence | The ultimate craftsmanship behind the polishing process of A&E baseball bat

-

Process innovation | A&E automatic batching system put into use

-

Quality control upgrade | A&E adds X-ray detection equipment to achieve zero defect goal in products

-